| |

| META TOPICPARENT |

name="WebHome" |

%DASHBOARD{ section="banner" |

| | titlestyle="color:#F00000;"

}%

|

|

<

< | GEM/Olympia #118, '66-run

Some pictures from the seller's website http://trainmaster.ch/ #118, '66-run

Some pictures from the seller's website http://trainmaster.ch/ Original open frame motor. It draws about 500 mA on the test stand. Reduction gear 1:28, 40x20x12 mm open frame motor

Original open frame motor. It draws about 500 mA on the test stand. Reduction gear 1:28, 40x20x12 mm open frame motor

|

| |

|

|

<

< | |

| | |

|

>

> | |

| |

|

|

>

> | |

| | |

| | |

|

>

> | |

| | |

|

<

< |

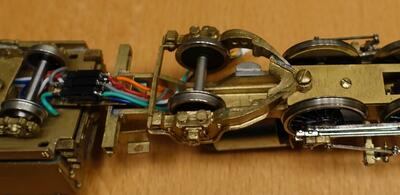

I replaced the open frame motor with a coreless DC motor (Maxon A-max16 12V/2W).

Datasheet , Distrelec part number 154-22-100.

Calculation for the motor speed: , Distrelec part number 154-22-100.

Calculation for the motor speed:

- 80 in drivers (scale 23.4 mm)

- max. speed 115 mph (185 km/h, 51.4 m/s, scale speed 590 mm/s, 8/s, 483/min)

- Reduction gear 1:28, 13.500/min

Values at 12 V

| |

|

110065 |

| Leerlaufdrehzahl |

11500 min-1 |

11700 min-1 |

| Leerlaufstrom |

41 mA |

32.3 mA |

| Nenndrehzahl |

5460 min-1 |

5430 |

| Nennmoment (max. Dauerdrehmoment) |

2.34 mNm |

2.39 mNm |

| Nennstrom (max. Dauerbelastungsstrom) |

0.293 A |

0.293 A |

| Anhaltemoment |

4.78 mNm |

4.76 mNm |

| Anlaufstrom |

0.521 A |

0.519 A |

| Max. Wirkungsgrad |

52 % |

56 % |

| Drehmomentkonstante k |

|

9.17 mNm/A |

k = (U0 - I0 Rm) / w0 = (12 - 32.3 mA 23.1) / (2 Pi (11700 / 60)) = 9.185 mNm/A |

| | Shafts and U-Joints from NWSL |

|

<

< |

- 2015-4 1.5 mm shaft

- 2024-4 2.4 mm shaft

- 483-6 U-Joint

You can get it from Old Pullman or direct from NorthWest Short Line or direct from NorthWest Short Line . .

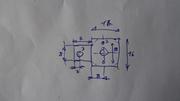

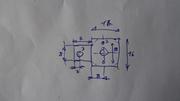

Sketch Bracket, brass 0.5 mm thick |

| |

|

|

<

< | |

| | |

|

>

> | |

| |

|

|

<

< | |

| | |

|

>

> | |

| | Docs

Soundtraxx Tsunami2 TSU-2200 |

| |

| Green |

9 |

5 |

FX3 (Ashpan Flicker CV 51: 23+128=151, F24) |

| Blue |

6 |

6 |

Function Common (+12V) |

|

|

<

< |

|

| | Tender

|

| |

| Blue |

- |

Current Keeper [Function Common (+12V)?] |

| Black |

- |

Current Keeper [Ground?] |

|

|

<

< |

|

| |

Spare

|

| |

https://sites.google.com/site/markgurries/home/decoders/decoder-motor-tuning/soundtraxx |

|

<

< | Notes from the Internet:

- CV213/14: Adjusting CV213 can achieve very good low speed at the expense of full speed. You have to strike a balance but try values between 5 & 10. The default setting of 15 in both CV213/14 appears to be too high for a lot of motors. But keep CV213/14 set to the same value what ever you end up with. Setting CV214 to a value 3x CV213 will stop the motor in its tracks unless you bring the speed step way up.

- There is a report that using the User Defined Speed Table CV 25 defeats the BEMF tweaks you make. The idea here was to make up for the effects CV213 had on the speed range. [3]

- Recent test that achieve good results with CV213/14 set to 5 first. Then set CV209 (Proportional) to max 255. Then reduce CV212 (Intensity) to get it to run smooth which was about 80. Playing with CV210 (Static) did not seem to change much at slow speeds.

Mark G Notes:

- It seems that CV213 is the first one to set for low speed performance before doing anything else. Given the BEMF is weakest at low speeds, you need to increase the sample rate (decrease sample period or make CV213 smaller) to increase the BEMF data to obtain any chance of good BEMF performance. The question is what to set the other CV’s to allow you to determine the best setting of CV213. This concept appears to be correct based on one credible internet report. Procedure: Leave all other BEMF CV’s at their factory default and only adjusting CV213 and 214 down between 5 and 10 but with identical values between the two will improve performance. A value of 8 is a good place to start.

- Given CV213 effect on top speed, it seems that CV213 should be dynamic and may in fact be the trick used by other BEMF decoders to get extended slow speed performance. Sample period goes up as the speed step goes down. Sample period goes down and the speed step goes up. This would get you the best of both worlds.

- Adjustment should be done with momentum and start voltage all set to zero. [1]

|

| |

Headlight |

|

<

< |

- Cal Scale HO PRR Headlight #190-477

- Cal Scale HO Headlight PRR Modern #190-235

- Cal Scale HO PRR Headlight Bracket #190-478

|

| |

|